China Professional Sfr Industrial Elevator Leaf Flat Top Drag Link Welded Cast Drive Roller Chain

Product Description

Stainless steel chains are widely used in various industries such as food processing, pharmaceuticals, chemicals, rubber processing, and more. These chains are essential for mechanical transmission and conveying equipment in fields like non-ferrous metal smelting, electronic equipment, and environmental protection equipment.

Our traction chains find applications in forklifts, stackers, textile machinery, parking garages, drilling rigs, aerial work platforms, and pipe benders. They provide reliable and efficient traction for these machines.

Drive chains play a crucial role in transmitting power and are extensively used in agricultural machinery, construction machinery, escalator drives, and logistics and packaging machinery industries.

Conveyor chains are widely used in industries such as food, wood and paper, logistics, packaging machinery, and building materials. They are employed for efficient and smooth material conveying.

Agricultural Machinery Chain

Our agricultural machinery chains are designed to support the mechanization of the entire agricultural production process. They provide driving and conveying functions for various agricultural machinery, including those used in rice, wheat, corn, and cotton production.

Conveyor Chain

Our conveyor chain products are characterized by their high strength, wear resistance, precision, corrosion resistance, and temperature resistance. They are the ideal choice for efficient and reliable material conveying in various industries.

Drive Chains

Our drive chains are manufactured using high-quality materials and advanced technology. They offer exceptional wear resistance, fatigue strength, and precision, making them suitable for agricultural machinery, construction machinery, escalator drives, and more.

Product Parameters

Company Profile:

EVER-POWER GROUP is a leading supplier of industrial products, offering a wide range of high-quality and innovative solutions. Our product portfolio includes agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more.

We take pride in our commitment to research and development, resulting in over 70 patents. Our manufacturing facilities are ISO9002, ISO9001, and ISO/TS16949 certified, ensuring the highest quality standards.

With over 30 years of experience, EVER-POWER GROUP exports to more than 60 countries worldwide. Our products are widely used in agriculture, motorcycle manufacturing, metallurgy, wood processing, food and beverage processing, and many other industries.

We continuously invest in manufacturing and R&D, embracing Industry 4.0. This enables us to offer a wide range of power transmission and conveyor chain solutions at competitive prices.

FAQs (Frequently Asked Questions)

1. What industries can benefit from stainless steel chains?

Stainless steel chains are widely used in industries such as food processing, pharmaceuticals, chemicals, rubber processing, and more. They are essential for mechanical transmission and conveying equipment in various fields.

2. Are your traction chains suitable for all types of machines?

Yes, our traction chains are designed to provide reliable traction for a wide range of machines, including forklifts, stackers, textile machinery, parking garages, drilling rigs, aerial work platforms, and pipe benders.

3. What makes your drive chains stand out?

Our drive chains are manufactured using high-quality materials and advanced technology, resulting in exceptional wear resistance, fatigue strength, and precision. They are the preferred choice for agricultural machinery, construction machinery, escalator drives, and more.

4. How do conveyor chains benefit different industries?

Conveyor chains are highly beneficial in industries such as food, wood and paper, logistics, packaging machinery, and building materials. They provide efficient and smooth material conveying for improved productivity.

5. What products does EVER-POWER GROUP offer apart from chains?

Besides chains, EVER-POWER GROUP offers a diverse range of industrial products such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We strive to provide high-quality products, competitive prices, and excellent customer service.

All the content of this page is from the Internet and is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory.

Performance Characteristics of Drive Chain

Drive chains offer several performance characteristics that make them a reliable choice for various applications:

- Durability: Drive chains are known for their high strength and resistance to wear and tear, ensuring long-lasting performance.

- Efficiency: Drive chains provide efficient power transmission, minimizing energy loss during operation.

- Flexibility: Drive chains can accommodate different operating conditions, making them suitable for a wide range of applications.

- Low maintenance: Drive chains require minimal maintenance, reducing downtime and overall costs.

Types and Characteristics of Drive Chain

Drive chains come in various types, each with unique characteristics:

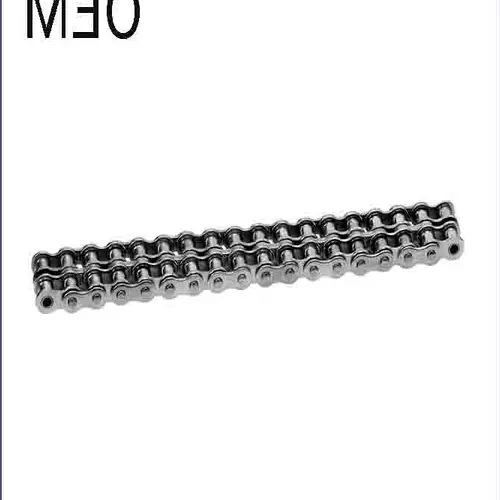

Roller Chains

Roller chains are the most common type of drive chain. They consist of interconnected rollers that engage with sprockets, providing smooth and reliable power transmission.

Silent Chains

Silent chains, also known as inverted-tooth chains, offer reduced noise and vibration levels compared to traditional roller chains. They are commonly used in applications that require quiet operation.

Leaf Chains

Leaf chains, also called balance chains, are designed for heavy-duty applications. They are known for their high tensile strength and resistance to shock and fatigue.

O-Ring Chains

O-ring chains have rubber O-rings between the roller link plates, providing lubrication and protection against contaminants. They are suitable for applications that require low maintenance and high resistance to corrosion.

Advantages of Drive Chain Materials

The material used in the construction of drive chains plays a crucial role in their performance. Here are some advantages of different drive chain materials:

Stainless Steel Drive Chains

Stainless steel drive chains offer excellent corrosion resistance, making them ideal for applications exposed to moisture or chemicals.

Nickel-Plated Drive Chains

Nickel-plated drive chains provide increased durability and protection against rust and wear. They are commonly used in harsh operating environments.

Carbon Steel Drive Chains

Carbon steel drive chains offer high tensile strength and are cost-effective. They are widely used in various industries.

Application of Drive Chain

The versatility of drive chains is evident through their widespread application in different fields:

Automotive Industry

Drive chains are extensively used in automobiles for power transmission in engines, drivetrains, and other components.

Industrial Machinery

Drive chains play a vital role in industrial machinery, ensuring efficient power transfer in manufacturing processes and heavy-duty equipment.

Agricultural Equipment

Drive chains are essential in agricultural machinery, such as tractors and harvesters, enabling efficient operation in challenging farming conditions.

Construction Equipment

Construction machinery heavily relies on drive chains for tasks like lifting, digging, and material handling.

Bicycles

Drive chains are a fundamental component of bicycles, facilitating pedaling motion and power transmission.

Future Development Trends and Opportunities

The drive chain industry is expected to witness several development trends and opportunities:

- Increased demand for energy-efficient drive chain solutions in various industries.

- Technological advancements leading to the development of lightweight yet durable drive chains.

- Growing focus on environmentally friendly drive chain materials and manufacturing processes.

- Expanding applications in emerging markets, such as electric vehicles and renewable energy sectors.

These trends present promising prospects for the drive chain industry, fostering innovation and market growth.

Choosing a Suitable Drive Chain

When selecting a drive chain, consider the following aspects:

- Determine application requirements: Identify the specific needs and operating conditions of your application.

- Load Capacity: Ensure the drive chain can handle the required load without compromising performance.

- Speed: Consider the desired operating speed and select a drive chain suitable for the application.

- Environmental Conditions: Assess environmental factors like temperature, moisture, and chemical exposure.

- Material: Choose a drive chain material that aligns with your application’s requirements and budget.

By carefully considering these factors, you can ensure the optimal performance and longevity of your drive chain.

In conclusion, drive chains offer exceptional performance characteristics, versatile types, and varied material advantages. Their extensive application in various industries highlights their irreplaceable value. As the drive chain industry continues to evolve, it holds promising opportunities for growth and development. By understanding the selection criteria, you can choose the perfect drive chain for your specific application.

Author: Dream